Program Information

Shipyard Infrastructure Optimization Program

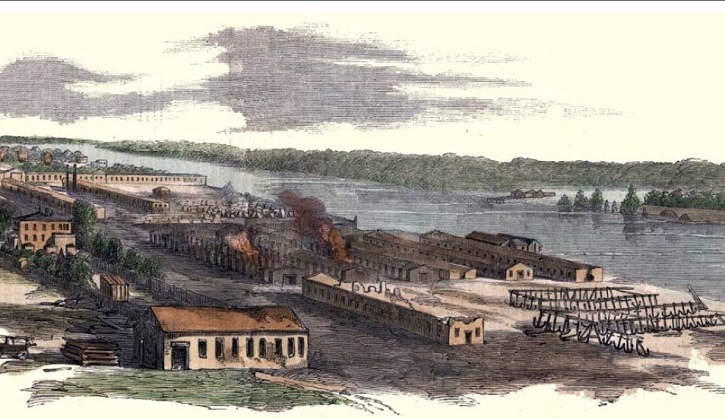

Harper’s Weekly Illustration of the Norfolk Naval Shipyard, 1861

Program Summary

The Navy’s four public shipyards – Norfolk Naval Shipyard, Pearl Harbor Naval Shipyard, Portsmouth Naval Shipyard, Puget Sound Naval Shipyard, and supporting Intermediate Maintenance Facilities, are essential elements of our seagoing national defense. The public shipyards are government-owned and -operated to ensure effective and timely maintenance for the Navy’s ships to meet required Fleet readiness. Their primary mission is to provide depot-level maintenance so that the Navy’s nuclear-powered aircraft carriers and submarines are available to meet the nation’s needs. Ship depot-level maintenance involves materiel maintenance or repair requiring the overhaul, upgrading, or rebuilding of parts, assemblies, or subassemblies, and testing and reclamation of equipment, as necessary. Ship intermediate-level maintenance includes calibrating, repairing, or replacing damaged parts; manufacturing critical unavailable parts; and providing technical assistance.

Aerial Image of Pearl Harbor Naval Shipyard on October 10, 1941

The current condition, configuration, and location of supporting facilities, dry docks and equipment limits the improvements that can be made to the Naval Shipyards. Planned growth in both the nuclear-powered aircraft carrier (CVN) and attack submarine (SSN) force will further exacerbate these challenges. The shortfalls in current capacity were documented in a Government Accountability Office (GAO) Report (Actions Needed to Improve Poor Conditions that Affect Operations, GAO 17-548, September 2017) that found that the inadequate and ill-configured dry docks, facilities, and equipment at the Naval Shipyards affect their ability to meet the Navy’s mission requirements.

The Shipyard Infrastructure Optimization Program (SIOP) will address infrastructure deficiencies to increase maintenance capacity by focusing on three major areas for each of the Naval Shipyards:- Dry dock capacity, configuration, and sustainability

- Facility layout and optimization

- Capital equipment modernization

Dry Dock Capacity, Configuration, and Survivability

Dry dock modifications are necessary to support USS GERALD R FORD Class (CVN, the current class of nuclear-powered aircraft carrier), USS VIRGINIA Class (SSN, current class of nuclear-powered submarine), and next-generation submarines, and to provide seismic and flood protection improvements. The dry dock capacity deficit noted in GAO Report 17-548 may be further aggravated by unplanned emergent U.S. Navy Fleet repairs and unanticipated national security contingencies. If not improved, an estimated 68 major scheduled maintenance periods will be missed or delayed, primarily due to dry dock obsolescence. Navy vessels require regular maintenance to operate safely and effectively, and missed or delayed maintenance decrements the expected lifespan of the vessel. Successful implementation of the SIOP is anticipated to restore 67 of the 68 scheduled maintenance periods.

Historic Image of Portsmouth Naval Shipyard

Facility Layout and Optimization

The Naval Shipyards comprise an infrastructure primarily designed for ship construction using early 20th century industrial models. Few major updates have been made since the early 20th century. Constrained facilities and functional layouts create significant production inefficiencies for the maintenance mission required for today’s nuclear-powered ships.

The material condition of the Naval Shipyard production facilities is poor (per Department of Defense (DoD) facilities conditions standards). These facilities and supported functions are not arranged or configured to best support nuclear-powered submarine or aircraft carrier depot- maintenance throughput.

Steps I and II of the SIOP involve analysis of current workflow and development of design strategies to optimize the four public shipyards to best execute current and future mission requirements, and address the deficiencies identified in another GAO Report (Key Actions Remain to Improve Infrastructure to Better Support Navy Operations, GAO-20-64, November 2019). The goal is to reduce, at a minimum, personnel and material travel and movement performed for each future submarine and aircraft carrier availability by an average of 65 percent, which equates to recovering 328K man-days of work per year. Reducing the duration of maintenance activities is a key step to improving overall performance of mission-critical work at each shipyard.

Further analysis will refine these estimates and, when combined with other ongoing industrial engineering innovations and capital improvements, will lead to larger process improvements within the facilities themselves that will result in significant increases in productive capacity.

1931 Photograph of Dry Dock 2 at Puget Sound Naval Shipyard

Capital Equipment Modernization and Location Optimization

Most capital equipment infrastructure at the Naval Shipyards is well beyond effective service life, obsolete, unsupported by original equipment manufacturers, and at operational risk. The private-sector’s average age for industrial equipment is 7 to 10 years, while the Naval Shipyards’ average age for capital equipment is 24 years. Nearly 70 percent of shipyard capital equipment is more than 10 years old, and almost 40 percent is more than 20 years old. Continued reliance on this aged equipment infrastructure increases submarine and aircraft carrier depot-maintenance availability costs and places schedules at risk. Modernizing capital equipment at the Naval Shipyards is essential to improve efficiency, reduce costs, meet future capabilities and provide Fleet readiness.

Additional equipment investments are also needed to support new mission requirements, including USS VIRGINIA Class availabilities at Portsmouth Naval Shipyard and Pearl Harbor Naval Shipyard and Intermediate Maintenance Facility, USS VIRGINIA Class introduction at Norfolk Naval Shipyard, and USS GERALD R FORD Class introduction at Norfolk Naval Shipyard and Puget Sound Naval Shipyard and Intermediate Maintenance Facility.